Can’t-Miss Takeaways Of Tips About How To Build A Centrifugal Pump

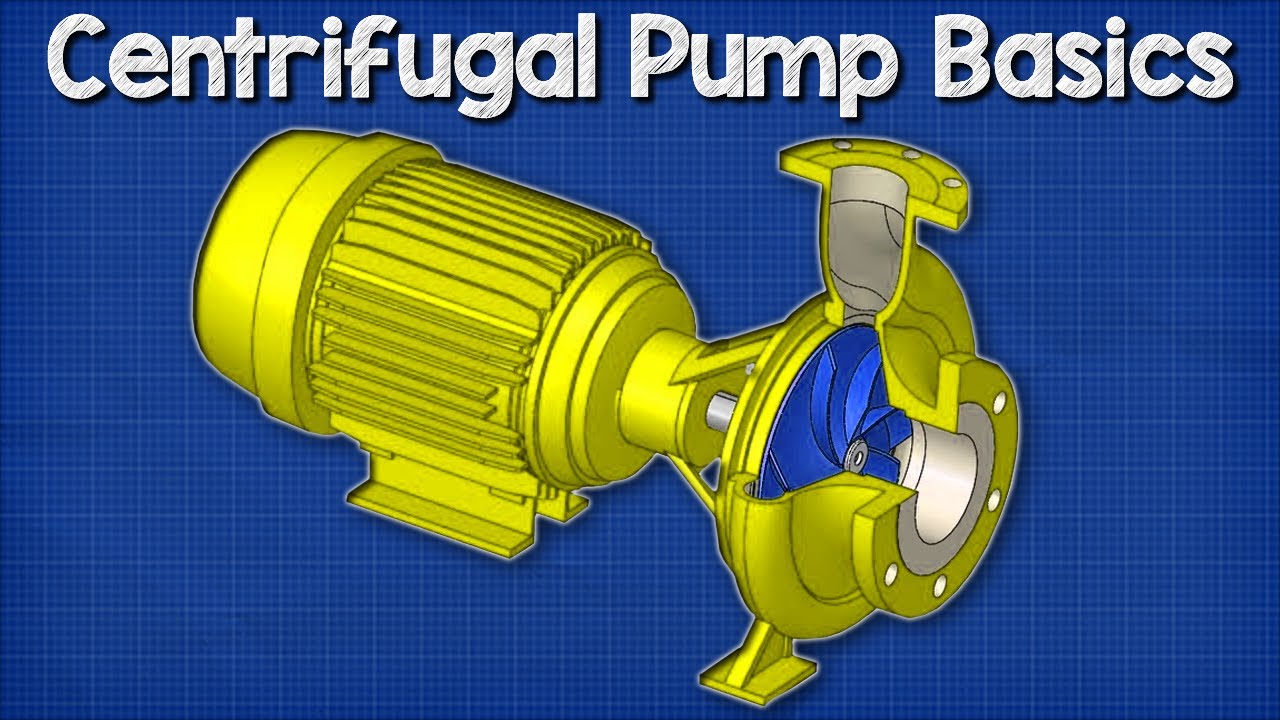

The closed type and the open type impeller.

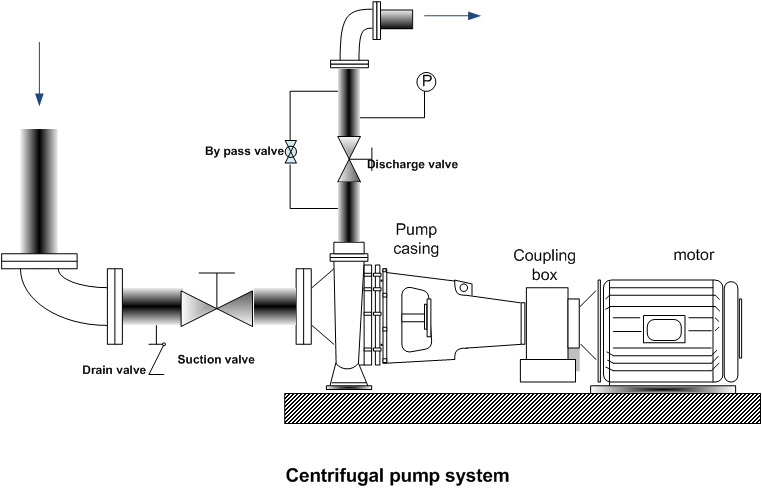

How to build a centrifugal pump. Decide what materials you need to pump and at what speed. Centrifugal pumps move fluid by using centrifugal force to generate velocity of the liquid. However all pump systems are different, in some systems the friction energy may represent 100% of the pump's energy, this is what.

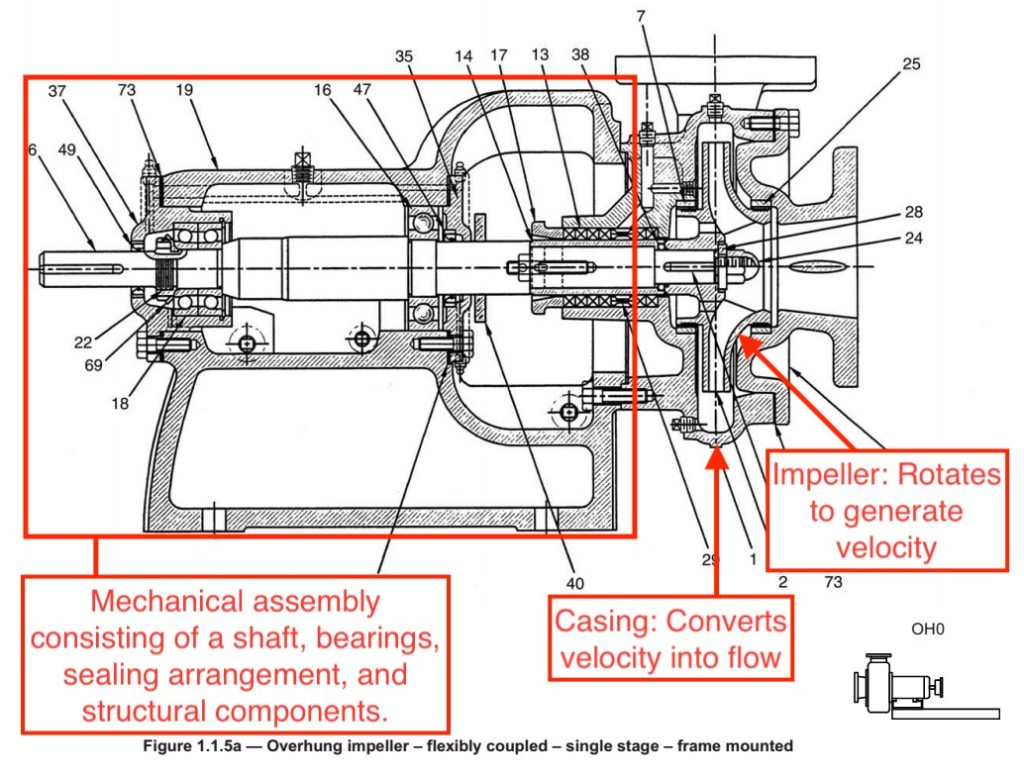

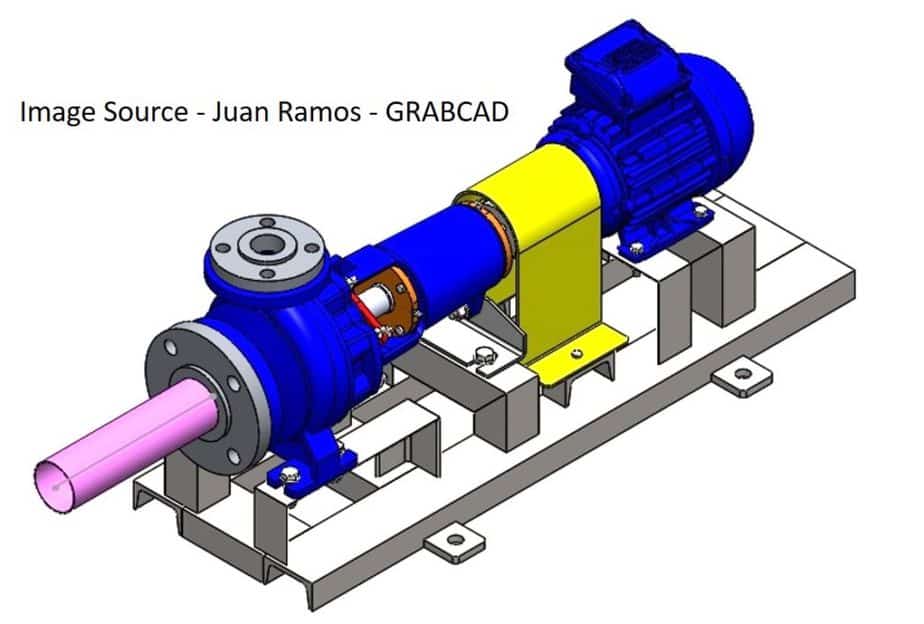

See also item 30 on selecting high speed centrifugal. Ensure that the foundation on which the centrifugal pump is mounted on is hard. Contruction of impeller in building the pump, the box and the impeller are assembled.

The structure of centrifugal pumps a centrifugal pump consists of a set of components that some (e.g., shaft, bearing, etc.) are responsible for maintaining the. When you order your pump make sure that the motor is installed with spacer blocks so that the next largest motor frame can be installed. There are two main impeller models:

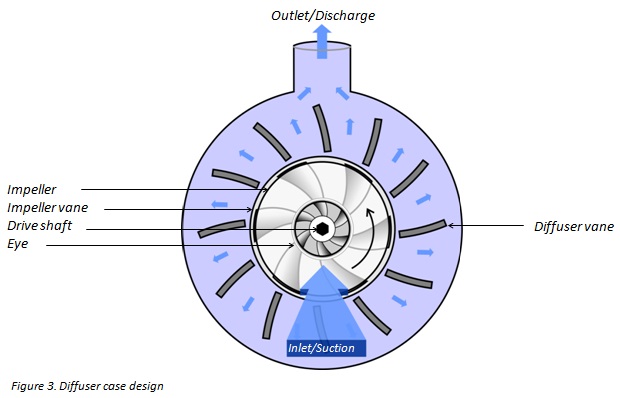

Fluid enters the pump through the suction nozzle, into the eye of the impeller. The specific gravity and viscosity of a material as well as how corrosive or abrasive it is will inform the type of impeller or turbine. Open impellers, which look similar.

Examine the system to see if the pipes are too small. This water pump is very simple to make. Here’s the part i’m most excited about:

How to make a self priming centrifugal pump step 1: Hello everyone!today i show you how to make a water pump using pvc pipe. These should be as thick as the mould for the outer.

/images/uploads/diy-WATER-PUMP.jpg)